B I

BI SYSTEMS Srl

info@bisystems-srl.it - www.bisystems-srl.it

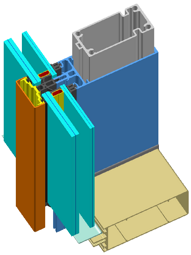

Series: BI48-F

BI48-F is the classic facade with Folder and Pressor. The novelties are many but not only its thickness in sight of just 48 mm, without compromising neither the strength nor the stresses to which the range of Uprights must respond. Accessories, if we can define them that way, do not exist.

Let's say that the accessories arrive in 6.5-meter bars, oxidized Silver, and are cut to size with a "step by step" miter saw and then the processing is carried out with a press. It is not excluded that they cannot be ordered cut and processed and the cost will remain very negligible and convenient.

Well BI SYSTEMS srls wanted to delocalize the production of accessories to the window maker, by doing so, not only the costs of the single piece are reduced, but the warehouse is eliminated by not filling it with hundreds of boxes and also preserving the same nature without further elimination of trees for making paper or other sources for making plastics that increase other harmful substances released into the air.

The screws are for commercial use available in any hardware store, not monopolizing the purchase.

There are only two gaskets, (One Presser and the other the Upright) and also in this case the savings are considerable both because there are only two and also because one size has been chosen without aggravating it as a price per linear meter.

The "Folders" (15mm Upright and 13mm Traverse) with 48mm in sight, have a less invasive aesthetic as a depth, considerably eliminating the deposit of dirt and helping to reduce its specific weight, therefore less aluminum, less cost, less pollution. They do not need slots for drainage and ventilation, which would make a "dirty" and not very aesthetic job visible, so everything is conveyed through the fins of the Spacer and the large chambers of the Upright.

Particular attention in designing the Spacer, it was decided to put two fins in soft EPDM, while the rest in ABS, positioning them flush inside the external glass. In this way, the thermal and acoustic seal and any water infiltration are raised, it is blocked and conveyed to the Uprights where there are large drainage chambers.

As for the presser tightening screw, in addition to being a screw available in any hardware store, a nylon washer / bushing is interposed between the screw and the presser, so that it is thermally insulated, leaving a part of expansion free for the presser.

Particular attention has been focused on the plug / joint for expansion Uprights, also here in full harmony with the rest of the accessories, it simply fits into the Uprights.

Designed and designed with care and in its morphology it fits perfectly in the drainage chambers, allowing any water to flow out and favoring air recirculation.

Thanks also to the Uprights where sharp edges have been eliminated so that convective micro motions are created so that from these micro turbulences not only there is an excellent compromise for the recirculation of the air but do not create air / water bubbles, therefore the owing to the effect of molecular cohesion and the effect that the corner is rounded, it acquires speed and is immediately drained downstream.